Construction Site Excavation: Top 5 Essential Tips 2025

Construction site excavation is a crucial first step in any building project. It involves preparing the site to enable safe and effective construction. Key components include:

- Site preparation tasks: Clearing obstructions, leveling the ground.

- Excavation purpose: Preparing for foundations and utilities installation.

In construction, site preparation and excavation set the stage for success. Properly executed, they ensure that subsequent construction activities go smoothly, avoiding costly errors and delays. When planning is thorough, foundations can be laid safely, avoiding issues like underground pipe damage.

Excavation is not just about digging. It’s a precise process that involves soil assessment, site layout planning, and careful coordination with contractors. Whether you’re dealing with a complex urban project or simpler residential build, understanding each step of excavation is vital.

Understanding Construction Site Excavation

When it comes to construction site excavation, it’s not just about moving dirt. It’s a structured process that sets the foundation for a successful build. Let’s break it down step-by-step.

Excavation Process

The excavation process starts with a detailed site assessment. This involves understanding the land’s current state, including topography, soil type, and any existing underground utilities. This assessment helps in creating a precise site plan, which is crucial for avoiding surprises during excavation.

Once the site is assessed, the next step is soil removal. This is where the heavy machinery comes into play. Bulldozers and excavators are used to clear the land, removing any obstructions like rocks or debris. This step is essential to ensure a level ground for construction.

Foundation Preparation

After clearing the site, the focus shifts to foundation preparation. This involves grading the land to create a stable base for the building. Grading ensures that water flows away from the foundation, preventing future structural issues.

To prepare the foundation, it’s important to consider the soil’s composition. Different soil types require different preparation techniques. For example, sandy soil may need additional compaction, while clay-rich soil might require drainage solutions to prevent water retention.

Coordination and Precision

Excavation is a coordinated effort between various teams. From surveyors marking the land to engineers planning the layout, each step requires precision. The goal is to create a site that’s ready for utilities installation and further construction activities.

Importance of Accurate Planning

Accurate planning during excavation can save time and money. By knowing exactly where to dig and what to avoid, contractors can prevent issues like underground pipe damage or soil erosion. This foresight is crucial, especially in urban areas with complex underground networks.

In summary, construction site excavation is a meticulous process that involves more than just moving earth. It’s about preparing the site for a solid foundation and ensuring that all subsequent construction activities can proceed without a hitch. With careful planning and execution, excavation sets the stage for a successful build.

Types of Excavation in Construction

Excavation is more than just digging holes. It involves several specialized techniques custom to different construction needs. Let’s explore the main types of excavation in construction: trenching, drilling, tunneling, and dredging.

Trenching

Trenching is one of the most common excavation types. It involves digging narrow, long cuts into the ground. These trenches are crucial for installing utility lines, such as water, gas, and electricity. They’re also used for setting foundation footings and improving site drainage. Think of trenching as creating the veins and arteries of a construction project, ensuring vital services can reach every part of a building.

Drilling

Drilling is used when dealing with hard materials like rock. This method often involves the use of explosives to break apart rock and clear land. In construction, drilling is frequently employed for creating tunnels, mining, and even for setting deep foundations. Specialized rigs can also drill for oil, gas, and water wells. It’s a precision task, often guided by advanced technology to ensure accuracy and efficiency.

Tunneling

Tunneling is all about creating pathways underground. This method is essential for building roads, railways, and other transportation infrastructure beneath the surface. Tunneling can involve controlled blasting, conventional excavators, or tunnel boring machines. These machines, often referred to as “moles,” chew through rock and soil, creating a clear path for further construction. It’s a complex process that requires careful planning and execution to ensure safety and structural integrity.

Dredging

Dredging takes place underwater. It involves removing sediment and debris from the bottoms of lakes, rivers, or oceans. This process is vital for maintaining navigable waterways and for construction projects near water bodies. Dredgers, which are specialized machines, scoop up sediment and relocate it to other areas. Dredging ensures that ports remain operational and that new marine structures can be safely built.

Each type of excavation has its own set of challenges and requires specific tools and expertise. At M.T. Mayo Corp., we have the experience and equipment to handle these tasks efficiently and safely, ensuring your construction project starts on solid ground.

Step-by-Step Excavation Process

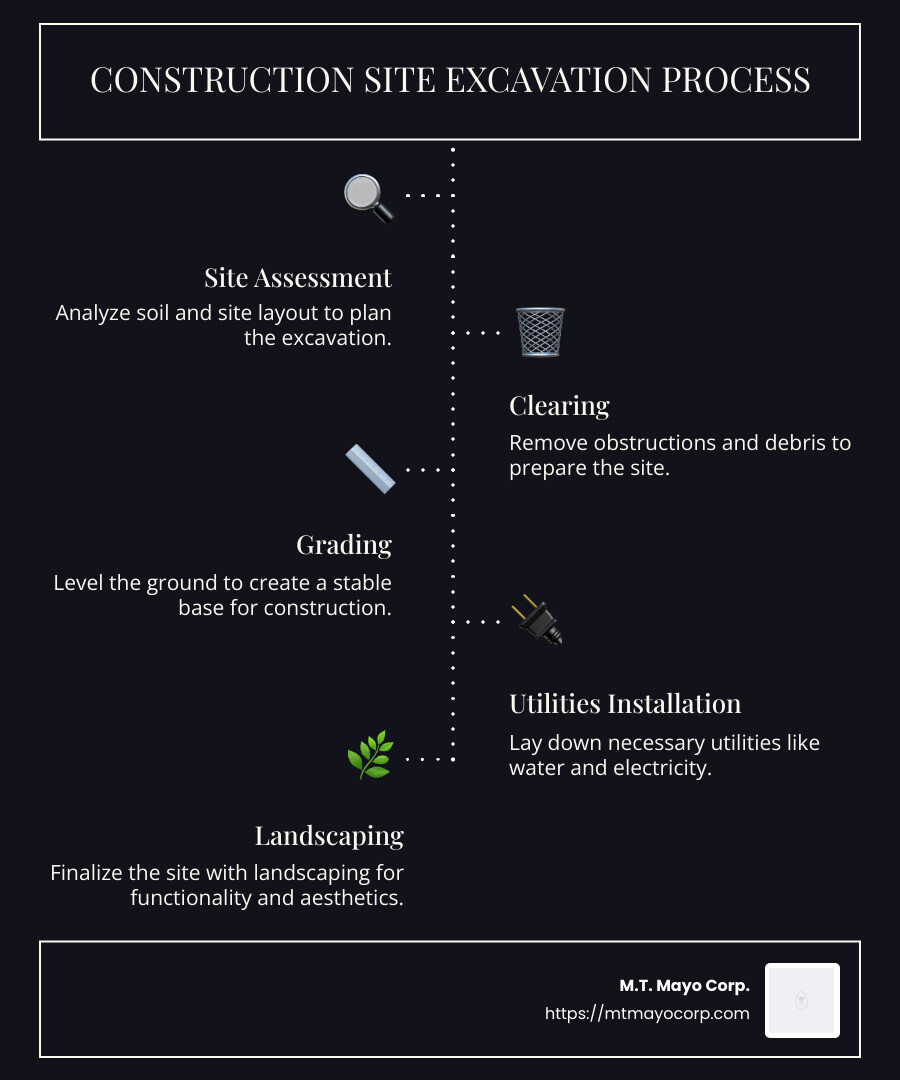

The construction site excavation process is a critical phase in preparing a site for building. It involves several key steps that ensure the land is ready for construction. Let’s break down each step to understand what goes into preparing a site from dirt to foundation.

Site Assessment

Before any digging begins, a thorough site assessment is conducted. This involves evaluating the land to understand its topography, soil composition, and any existing underground utilities or structures. Specialists, such as engineers or surveyors, use advanced technology to map out the site. This helps in identifying below-grade obstructions like rocks, which can affect both the budget and schedule of the project. Once the site plan is ready, it is sent for pricing, contractor selection, and permitting to ensure compliance with local ordinances.

Clearing

With the plan in place, the next step is clearing the land. This involves removing trees, brush, and any old buildings or structures. The goal is to create a smooth, empty slate for the project to begin. The waste generated is transported offsite for proper disposal or recycling. During this phase, erosion control measures are crucial. Removing vegetation can lead to loose soil, which can easily be eroded by wind and rain. Therefore, the team must follow local, state, and national erosion-control standards to prevent soil from entering waterways.

Grading

Grading is about shaping the land to create a level base for construction. It involves cutting and filling the soil to achieve the desired slope and elevation. Proper grading ensures that water drains away from the building, preventing future water damage. This step is crucial for the stability of the foundation and overall site drainage.

Utilities Installation

After grading, the installation of utilities such as water, gas, electricity, and sewage lines begins. This step is essential for ensuring that the building has all the necessary services. Trenching is often used to lay these utility lines underground. It’s important to coordinate with utility companies to ensure safe and efficient installation.

Landscaping

Once the heavy lifting is done, landscaping takes place. This step involves planting trees, shrubs, and grass to improve the aesthetic appeal of the site. Landscaping also plays a functional role in controlling erosion and managing stormwater. It’s the final touch that transforms a construction site into a welcoming environment.

Each step in the excavation process is vital for laying a strong foundation for any construction project. At M.T. Mayo Corp., we ensure each phase is executed with precision and care, setting the stage for successful construction.

Safety and Compliance in Excavation

When it comes to construction site excavation, safety and compliance are top priorities. This process involves removing soil and rocks to prepare foundations, and it must be done with utmost care to protect workers and the environment. Let’s explore the essential safety measures, procedural prevention strategies, and compliance standards that ensure a smooth and secure excavation process.

Safety Measures

Safety is paramount on any excavation site. Here are some key practices:

- Personal Protective Equipment (PPE): Workers must wear hard hats, gloves, goggles, and steel-toed boots to protect against injuries.

- Site Inspection: Regular inspections help identify potential hazards like unstable soil or water accumulation.

- Trench Safety: Trenches deeper than 5 feet require protective systems like shoring or trench boxes to prevent collapses.

- Clear Communication: Use radios or hand signals to maintain clear communication among team members, ensuring everyone is aware of ongoing activities.

Procedural Prevention

Preventive measures are crucial to avoid accidents and ensure a successful excavation:

- Risk Assessment: Before starting, conduct a risk assessment to identify potential dangers and plan how to mitigate them.

- Training: Ensure all workers are trained in excavation safety and emergency procedures.

- Erosion Control: Implement erosion control measures, such as silt fences or hay bales, to prevent soil from washing away and contaminating nearby water bodies.

- Utilities Marking: Use utility maps and ground-penetrating radar to locate and mark underground utilities, avoiding accidental damage during digging.

Compliance Standards

Compliance with local, state, and national regulations is essential for legal and safe operations:

- Permits and Approvals: Obtain necessary permits before beginning excavation to ensure adherence to local laws and ordinances.

- OSHA Regulations: Follow OSHA’s excavation and trenching standards to maintain a safe work environment. This includes guidelines on sloping, shoring, and shielding.

- Environmental Protection: Comply with environmental regulations to protect surrounding ecosystems from excavation impacts.

At M.T. Mayo Corp., we prioritize safety and compliance in every project. By adhering to these standards, we ensure that our excavation work is not only efficient but also safe and environmentally responsible. This commitment to safety sets the stage for successful construction projects.

Frequently Asked Questions about Construction Site Excavation

What is the purpose of excavation in construction?

Excavation is crucial for preparing the foundation of any building. It involves removing soil and rocks to create a stable base for structures. Without a solid foundation, buildings can suffer from uneven settling or even collapse. Excavation also allows for the installation of utilities like water, gas, and electrical lines, ensuring that all necessary infrastructure is in place before construction begins.

How long does the excavation process take?

The duration of the excavation process depends on several factors:

- Project Size: Larger projects naturally take more time. For a small residential site, excavation might take a few days. On larger commercial sites, it could extend to several weeks.

- Soil Type: The type of soil can significantly affect the timeline. Sandy soils are easier to excavate, while clay or rocky soils require more effort and time.

- Weather Conditions: Rainy or snowy weather can delay excavation work, as it affects the soil’s stability and machinery efficiency.

What are the common types of excavation equipment?

Several machines are essential for efficient construction site excavation:

- Bulldozers: These powerful machines are used for pushing large quantities of soil and leveling the ground. They are ideal for clearing sites and creating rough grades.

- Excavators: These are versatile machines equipped with a bucket, arm, and rotating cab. They are used for digging trenches, holes, and foundations, as well as handling materials.

- Tracked Dumpers: These machines are perfect for transporting heavy materials over rough terrain. Their tracks provide better traction than wheels, making them ideal for challenging environments.

Understanding these factors and equipment ensures a smoother excavation process, setting the stage for successful construction. Next, we’ll dig into the various steps involved in the excavation process, from site assessment to landscaping.

Conclusion

At M.T. Mayo Corp., we pride ourselves on providing expert construction site excavation services that set the foundation for successful building projects. Our team is dedicated to delivering high-quality results with a strong focus on safety and compliance. Located in Woburn, MA, we serve a wide range of areas across Middlesex and Essex counties, ensuring that your project is in capable hands.

Our services extend beyond simple digging. We offer a comprehensive range of solutions, including site preparation, trenching, and foundation excavation. Our experienced team understands the complexities involved in each project, whether it’s clearing land, grading, or installing utilities.

Safety is at the core of everything we do. We adhere to strict safety standards and procedural prevention measures to protect both our workers and your property. Our team is fully licensed and insured, ensuring that every project is executed with the utmost care and professionalism.

For those looking to start a new construction project, choosing the right excavation partner is crucial. With over 20 years of experience, M.T. Mayo Corp. is the trusted choice for all your excavation needs. We invite you to learn more about our services and how we can assist with your next project.

Contact us today to discuss your excavation requirements and find how our expertise can bring your construction vision to life.